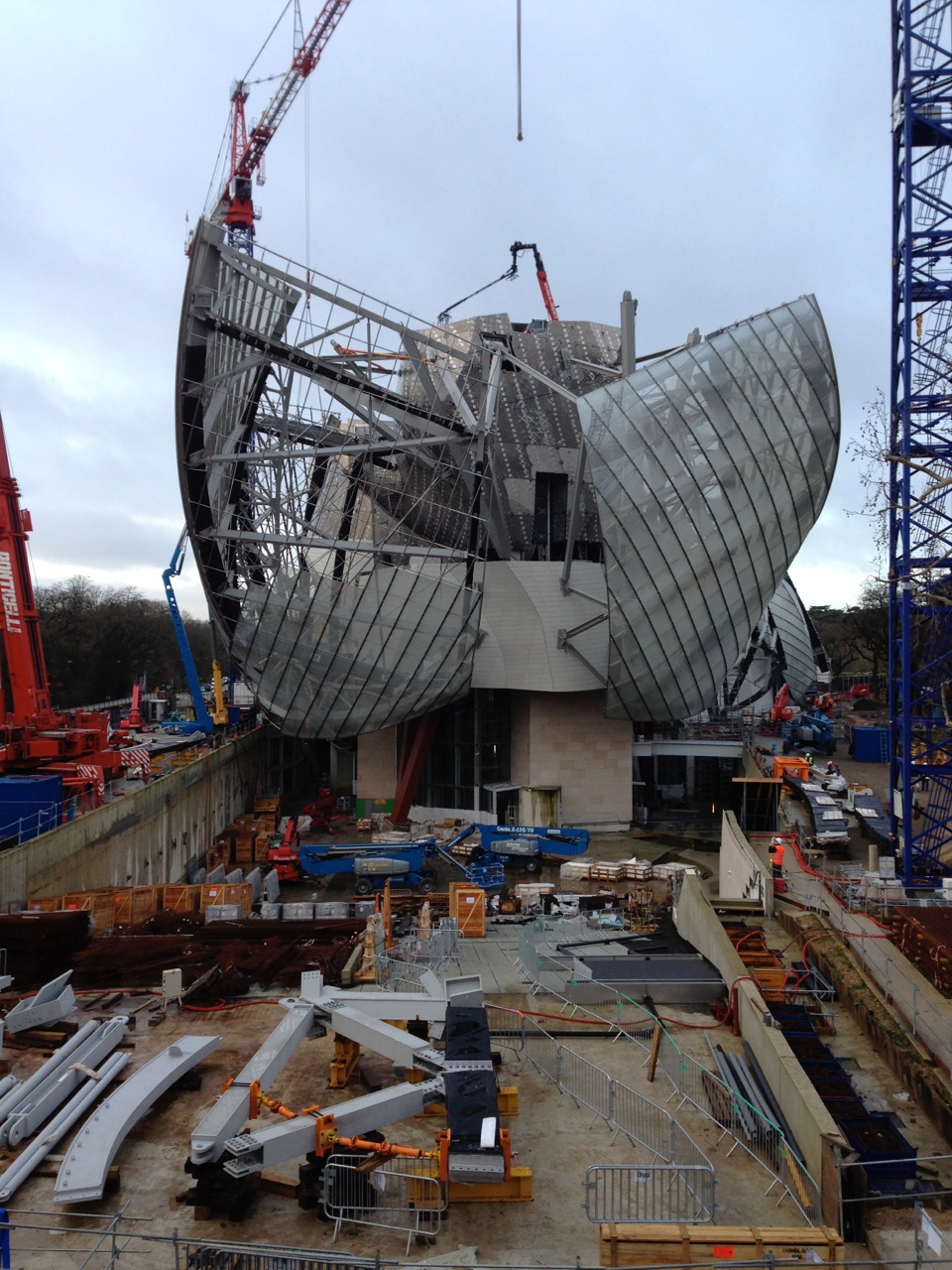

PALFINGER’s WT 350 Jumbo Class, WT 370 Premium Class, and P 900 Top Class platforms were deployed for cleaning, maintenance, and repair work on the new Louis Vuitton Museum in the heart of Paris.

This futuristic building, constructed from glass and steel, presented a real challenge—one perfectly suited to PALFINGER’s high-performance platforms, designed to operate at extreme heights while offering exceptional maneuverability and precise access to even the most complex architectural features. The entire cleaning project focused on protecting the building’s delicate façade from mechanical damage. PALFINGER’s engineering team provided a simple yet highly effective solution: all three platforms were equipped with special sensors in the work basket that alert the operator when in close proximity to the surface, significantly reducing the risk of collision or impact.

Permanently stationed on a concrete base at the upper level of the complex, the WT 350 handles roof maintenance with ease. The WT 370 and P 900 were used for cleaning the building’s glass sides, with the flexibility to move around the structure as needed. WT 370 focused on the lower parts of the façade, while the P 900 was assigned to the higher and more demanding sections.

Since cleaning is conducted overnight, minimizing noise was critical—something PALFINGER’s specialists successfully ensured with optimized operation settings.

The Louis Vuitton project managers expressed great satisfaction with PALFINGER’s performance, citing maximum safety, precision, and reliability as key advantages of the platforms used.