Mon 18.07.2022

THE NEW GENERATION 3

EXPERIENCE & TECHNOLOGY

We listened very closely to our customers when developing the new generation of cranes. Together, we grow with the challenges we face. Together, we recognize the potential on which we are working with a passion. By working together with a spirit of mutual trust, we have succeeded in adopting the best features of the previous crane series and combining them with the latest technological developments. The new GENERATION 3 combines the highest level of convenience with a very appealing design and purpose-specific technologies. Technologies that make our customers’ work easier while making them even more cost effective and environment friendly. That is because as a partner for generations, we know that a sustainable and resource-saving way of working is the only way to ensure a future suitable for the next generations.

INTERVIEW

with Josef Leitner & Stefan Kopp

Josef: Iskustvo znači učenje – konstantan proces u kojemu su dobre i dokazane stvari usavršene. Testiranje novih stvari i isprobavanje nekonvencionalnog. Ali to također znači učenje iz grešaka – bitno ih je prepoznati i priznati. Dok god skupljate iskustvo, gradite vaše znanje i prije svega praktično znanje, nastavljate rasti i razvijati se. Ovaj razvoj se može vidjeti i osjetiti u novoj GENERACIJI 3.

Can you tell us more about your daily work:

What was the feedback from customers and how did it influence the new GENERATION 3?

Josef: Our customers know best what they need. For us, that means less talking, more listening. For me, in my work, it means being as close to our customers as possible. That means visiting them, talking to them directly, and doing this while they are working. In this way, we learn from the customer how he needs and wants his equipment. And that’s exactly what we’ve done for him with the new GENERATION 3: Reliability, durability, customer benefits and a little something for the eye.

Stefan is Product Manager for the new GENERATION 3 at EPSILON.

We’ve now heard quite a bit about experience, but how does the technology relate here?

How has the technology developed and improved with the new GENERATION 3? What can we expect?

Stefan: Without technology, our world would not be the way as it is today. As with experience, technology builds on what is known and proven. State-of-the-art, high-strength steels need adapted technologies to process them. Combined with our strength – experience in steel construction – the GENERATION 3 was born: Stronger, faster, more range, and all this with the same weight. New technologies were also used in the hydraulics. We take our cues from the feedback of our test drivers during set-up and tuning runs. In addition, countless sensors now record data – so to speak, a computer is driving along. Here, our premise is the same: If it works, then we accept new things. In this way, our experience only supplements and improves what’s new, but doesn’t replace it entirely.

HIGHLIGHTS

of the new GENERATION 3

- The longest reach in its class – up to 10.9 meters

- COMFORT DRIVE – the new control system including a new 360° light concept

- Centralized greasing options: automatic or manual

- SMART CONTROL – for the electric cab option

- New outtrigger options – support width up to 5.4 meters

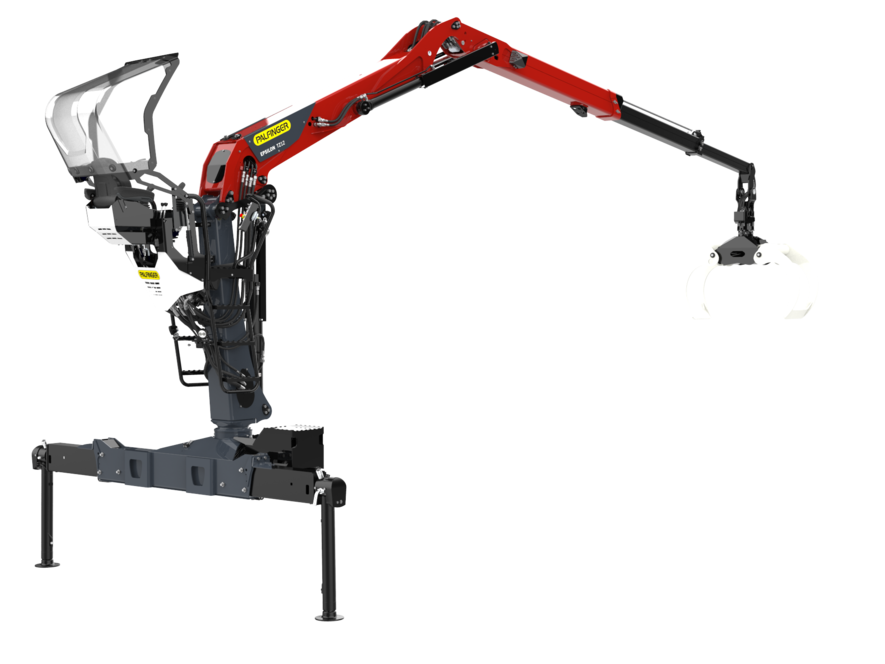

THE LONGEST REACH IN ITS CLASS

up to 10.9 meters

With a reach of almost eleven meters, the new GENERATION 3 once again offers the longest reach in its class. A significantly larger working arc when loading and comparatively fewer truck repositioning steps make work much more efficient. With the aim of building even stronger cranes without adding weight, we have completely redeveloped and extensively optimized the steel structure on the new GENERATION 3. Consequently, “long, longer, longest,” refers both to reach and service life.

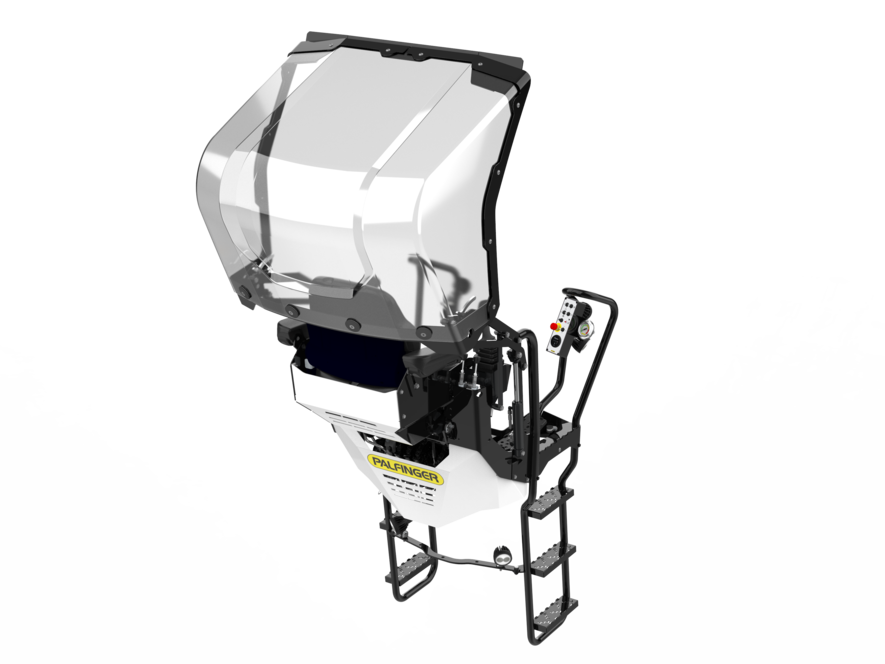

COMFORT DRIVE

including a new 360-degree light concept

Crane operators are clearly at the heart of our work. We developed the new, compact Comfort Drive for them. The result is maximum ergonomics while operating the crane and minimum fatigue during longer tasks. The Grammer seat features suspension for perfect comfort. Due to the hydraulic pilot system, the crane controls are highly sensitive and precise. The new joystick options give you a firm grasp of every situation.

If the days are too short for longer tasks, the new 360-degree lighting concept turns night into day to create optimal working conditions even in the dark. In addition to the two LED floodlights, four additional floodlights ensure perfect illumination of the entire work environment.

CENTRALIZED GREASING OPTIONS

automatic or manual

The new centralized greasing options also enhance efficiency during maintenance. Regardless of whether automatic or manual, both centralized greasing systems are fully integrated into the crane design to ensure consistently smooth operation of the crane right from the start.

With the automatic centralized greasing option, a dedicated pot automatically applies grease to the main axes of rotation. It is no longer necessary to grease each individual lubrication point. A quick check of the level of the grease pot is all it takes to ensure consistently smooth operation. With manual central greasing, the most important lubrication points can be greased quickly and easily from one central point using a grease gun.

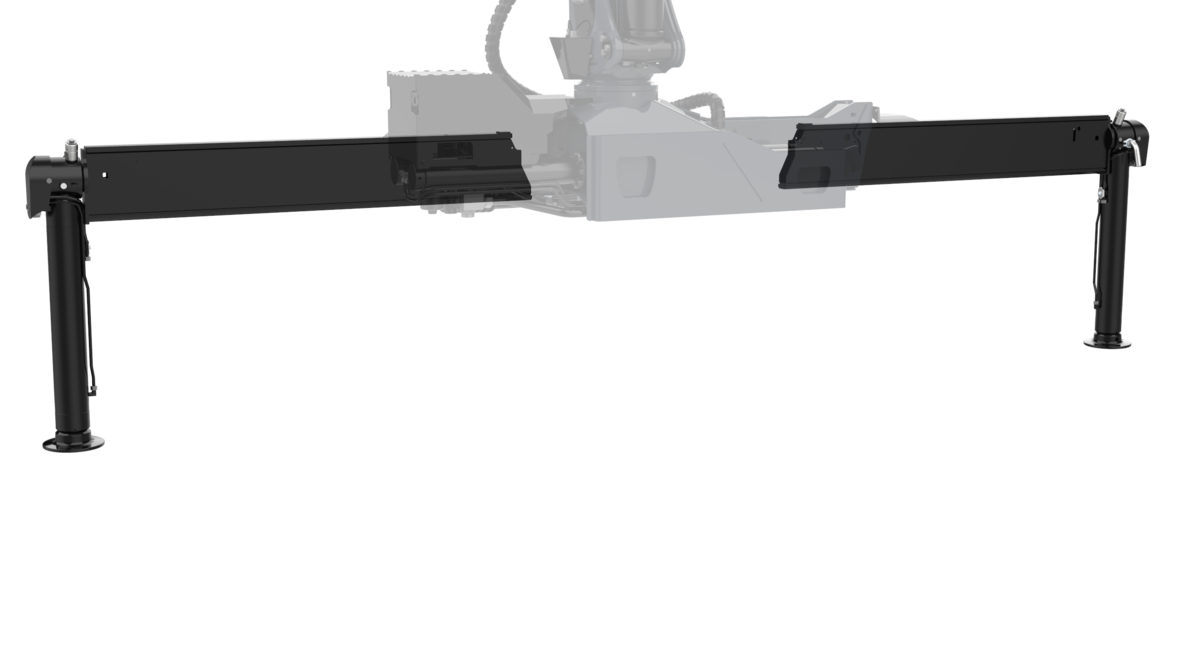

NEW OUTTRIGGER OPTIONS

support width up to 5.4 meters

The new outrigger options provide optimum stabilization with support widths of up to 5.4 meters while maintaining compact dimensions in the retracted position. This ensures even greater stability of the entire system, in particular when loading large loads with a long reach from the side. The internal hose routing also reduces the risk of damage to the hydraulics.

SMART CONTROL

the intelligent EPSILON assistance system

The new PALFINGER SMART CONTROL assistance system enables even faster and more intuitive crane operation and is available as an option on the new GENERATION 3 for on-road and off-road deployments. The locations of the sensors have already been taken into account when designing the cranes so they are fully integrated into the overall system. The SMART CONTROL sensors enable operators to concentrate fully on the tip of the crane. This makes it much easier to control the crane, minimizes fatigue and significantly reduces the time it takes to train new operators. Raising the bar in convenience and safety, the new Smart Control is initially available for L and Z cranes with the TEC CAB control system and GENERATION 3 double telescope models.