The company Beokran d.o.o. from Belgrade, specialized in the transport and handling of heavy loads, has taken delivery of a new Palfinger PK 1650 TEC crane, the most advanced model from the new-generation TEC series.

This heavy-duty crane is equipped with a G extension and an additional articulated fly-jib PJ240E, allowing for a vertical reach of over 35 meters and a horizontal reach of up to 21 meters. The maximum lifting capacity reaches up to 32,000 kg. The crane is operated via the advanced PALTRONIC 180 electronic control system combined with the high-precision LX-6 valve, ensuring smooth and safe handling of loads.

The crane includes a wide range of intelligent features that improve efficiency, safety, and ease of use:

Memory Position enables storage and automatic return to pre-defined working positions, streamlining repetitive tasks. Leveling Assistant automatically levels the vehicle via stabilizers, ensuring safe and optimal setup even on uneven terrain. AOS (Active Oscillation Suppression) reduces load swing during sudden movements, increasing overall stability. SRC (Synchronised Rope Control) maintains a consistent distance between the hook and rope pulley, enabling precise load positioning without manual adjustments. RTC (Rope Tension Control) automatically maintains rope tension during operation, preventing slack and ensuring safer lifting. DPS-C (Dual Power System – Continuous) unlocks additional lifting power beyond the standard load chart by intelligently optimizing capacity in real time. Soft Stop smooths crane arm movements by damping sudden stops, reducing mechanical stress and increasing comfort and safety.

Palfinger Connected provides real-time digital monitoring and management of crane status, maintenance needs, and performance via an app, helping to reduce downtime and optimize fleet efficiency.

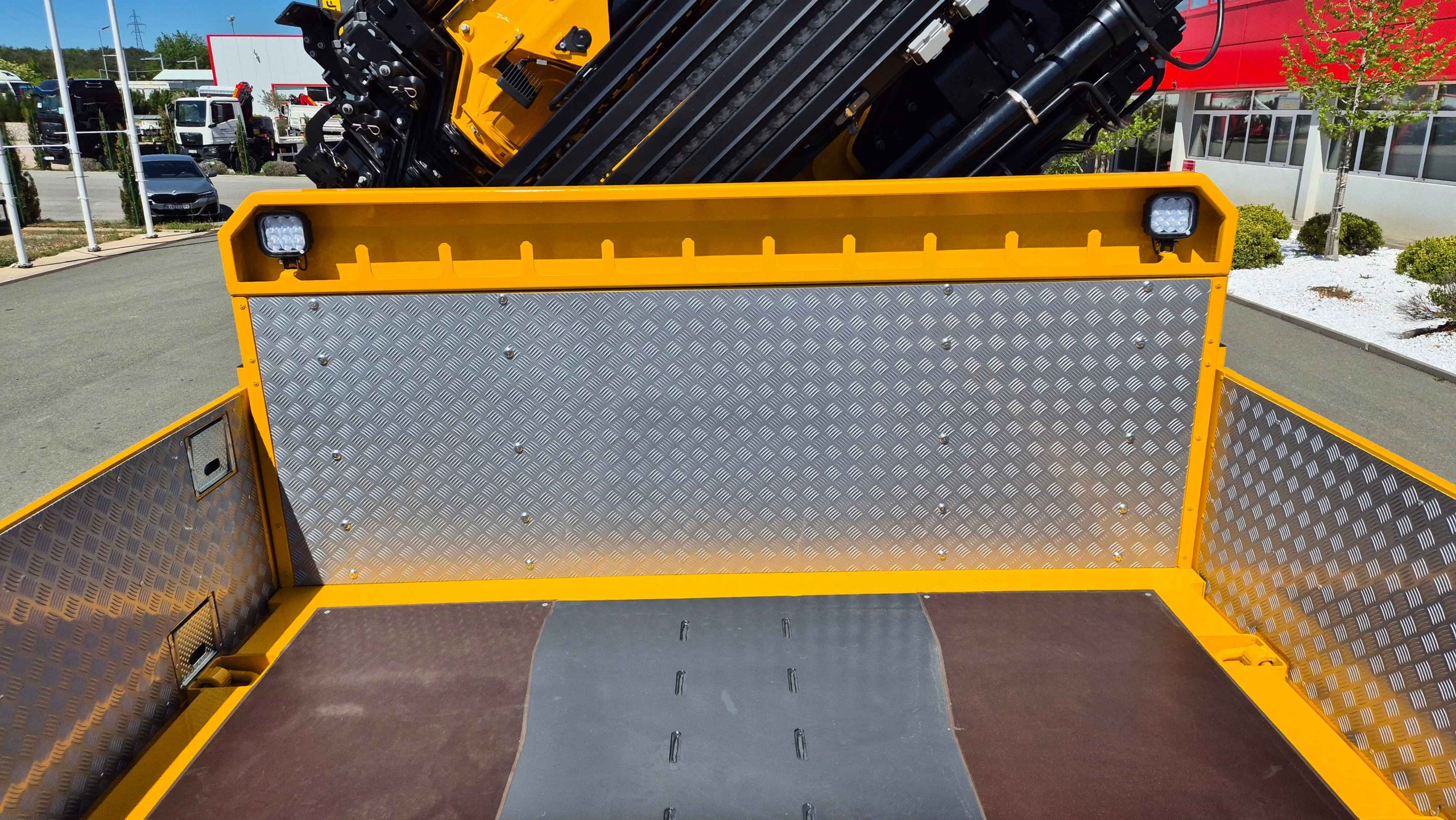

The superstructure is mounted on a Volvo FH500HP 10×4 Rigid chassis, featuring a TS-5.1 cargo platform with a useful internal length of 5,100 mm and a hydraulically extendable rear section of up to 1,000 mm for added flexibility when loading and unloading. For improved visibility and operational safety at night or in low-light conditions, the truck is also equipped with LED working lights.

Operator training was provided as part of the delivery process, making the entire setup immediately ready for demanding on-site applications.

Memory Position enables storage and automatic return to pre-defined working positions, streamlining repetitive tasks.

Palfinger Connected provides real-time digital monitoring and management of crane status, maintenance needs, and performance via an app, helping to reduce downtime and optimize fleet efficiency.

SRC (Synchronised Rope Control) maintains a consistent distance between the hook and rope pulley, enabling precise load positioning without manual adjustments.

RTC (Rope Tension Control) automatically maintains rope tension during operation, preventing slack and ensuring safer lifting.

AOS (Active Oscillation Suppression) reduces load swing during sudden movements, increasing overall stability.

Leveling Assistant automatically levels the vehicle via stabilizers, ensuring safe and optimal setup even on uneven terrain.

DPS-C (Dual Power System – Continuous) unlocks additional lifting power beyond the standard load chart by intelligently optimizing capacity in real time.

Soft Stop smooths crane arm movements by damping sudden stops, reducing mechanical stress and increasing comfort and safety.